The world is on the verge of a water crisis. Rainfall shifts caused by climate change plus the escalating water demands of a growing world population threaten society’s ability to meet its mounting needs. By 2025, the United Nations predicts, 2.4 billion people will live in regions of intense water scarcity, which may force as many as 700 million people from their homes in search of water by 2030.

Those water woes have people thirstily eyeing the more than one sextillion liters of water in Earth’s oceans and some underground aquifers with high salt content. For drinking or irrigation, the salt must come out of all those liters. And while desalination has been implemented in some areas — such as Israel and drought-stricken California — for much of the world, salt-removal is a prohibitively expensive energy drain.

Scientists and engineers, however, aren’t giving up on the quest for desalination solutions. The technology underlying modern desalination has been around for decades, “but we have not driven it in such a way as to be ubiquitous,” says UCLA chemical engineer Yoram Cohen. “That’s what we need to figure out: how to make desalination better, cheaper and more accessible.”

Recent innovations could bring costs down and make the technology more accessible. A new wonder material may make desalination plants more efficient. Solar-powered disks could also serve up freshwater with no need for electricity. Once freshwater is on tap, coastal floating farms could supply food to Earth’s most parched places, one scientist proposes.

Watering holes

Taking the salt out of water is hardly a new idea. In the fourth century B.C., Aristotle noted that Greek sailors would evaporate impure water, leaving the salt behind, and then condense the vapor to make drinkable water. In the 1800s, the advent of steam-powered travel and the subsequent need for water without corrosive salt for boilers prompted the first desalination patent, in England.

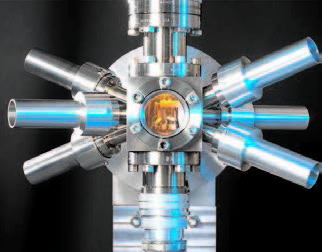

Most modern desalination plants use a technique that differs from these earlier efforts. Instead of evaporating water, pumps force pressurized saltwater from the ocean or salty underground aquifers through special sheets. These membranes contain molecule-sized holes that act like club bouncers, allowing water to pass through while blocking salt and other contaminants.

The membranes are rolled like rugs and stuffed into meter-long tubes with additional layers that direct water flow and provide structural support. A large desalination plant uses tens of thousands of membranes that fill a warehouse. This process is known as reverse osmosis and the result is salt-free water plus a salty brine waste product that is typically pumped underground or diluted with seawater and released back into the ocean. It takes about 2.5 liters of seawater to make 1 liter of freshwater.

Be the first to comment