The European Space Agency (ESA) announced the winning industrial team that will design and build an experimental payload to extract oxygen from the regolith (lunar soil) on the surface of the Moon.The team is led by UK-based Thales Alenia Space and is tasked with producing a small solar-powered prototype device that will be used to evaluate the prospect of building oxygen-generation plants on the moon. This could be useful for generating oxygen that can be used as a propellant and for astronauts to breathe.

The compact payload designed by the team will have to extract between 50 and 100 grams of oxygen from the lunar regolith while targeting the extraction of 70 per cent of all available oxygen within the sample. The device will also have to do all this within a period of ten days, which is how long solar power will be available within a single lunar day before the pitch-black and freezing lunar night.

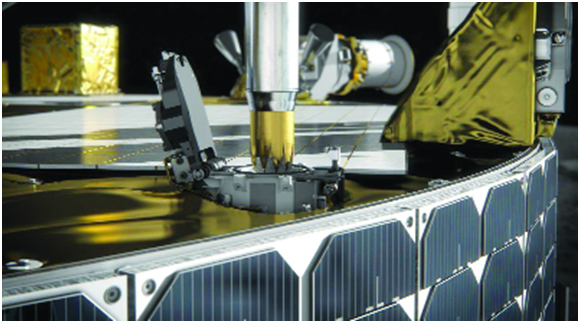

The payload is also required to be low power and able to fly on many different lunar landers including ESA’s own European Large Logistics Lander, EL3. The winning team that also consists of AVS, Metalysis, Open University and Redwire Space Europe was selected by the ESA’s Directorate of Human and Robotic Exploration in 2021 after conducting a detailed study including three rival designs.

According to David Binns, Systems Engineer at ESA’s Concurrent Design Facility (CDF), the ability to extract oxygen and other useable materials from lunar regolith will be a game-changer for lunar exploration, allowing astronauts to ‘live off the land’ without depending on long and expensive supply lines from the earth.

It had already previously been discovered that lunar regolith from the moon’s surface consists of 40-45% oxygen by weight. The problem is that this oxygen is bound up with other chemicals as oxides in the form of minerals or glass, making it unavailable for use without processing.

In 2020, the ESA had set up a prototype oxygen plant in the Materials and Electrical Components Laboratory of the European Space Research and Technology Centre, ESTEC, based in the Netherlands. The lab is used to extract oxygen from simulated regolith to fine-tune the process for efficiency.

Source: The Indian Express

Be the first to comment